Protecto Wrap

Protects OSB and plywood roof deck seams by preventing water from entering the home

Typically when constructing a roof, an 1/8″ gap is left to allow for expansion and contraction of the wood sheathing which can be susceptible to water intrusion. PROTECTO ROOF DECK SEAM TAPE is a self-adhering tape used to seal the seams of an OSB or plywood roof deck, and protect the structure by keeping water out. The 40 mil thickness meets ASTM D1970 while providing a waterproof, air and vapor barrier that is rated for six month UV exposure. This slip resistant, fully adhered system is made with high-temp rubberized asphalt adhesive which seals around properly installed fasteners and complies with IRC 2015 R 905.1.1.

Complies with IRC 2015 R 905.1.1

FEATURES & BENEFITS

- Helps prevent moisture penetration in roof deck seams

- Slip resistant surface film

- 40 mil thickness meets ASTM D1970

- Rubberized asphalt adhesive

- Seals around properly installed fasteners

- 6 month UV exposure

- Complies with IRC 2015 R 905.1.1

- High temp adhesive (250°F) can be used under metal roofing

ROOF DECK SEAM TAPE

PREPARATION:

Roof deck surface shall be clean, dry and free of any foreign materials. The roof deck surface shall be free of gaps, sharp edges and protrusions. Do not walk on surface when wet or covered with frost as there is an increase risk of injury.

Metal surfaces may need to be solvent wiped and/or abraded to achieve optimum adhesion. On vertical applications at roof to wall intersections, all surfaces shall be clean, dry and free of any foreign materials. The surface shall be free of gaps, sharp edges and protrusions. Protecto Wrap Company recommends testing substrates for adhesion prior to full application of tape. If adhesion to substrate is found to be marginal, then a primer shall be used to ensure optimal adhesion. Refer to: “Technical Letter Primer Recommendations”.

PRIMING:

Prime if surface is DensGlass Gold®, DensDeck, OSB, concrete substrates, Concrete block (CMU), masonry, fiber board sheathing, exterior gypsum or cannot be cleaned to a like new surface or the surface is damp or below 40°F (4°C).

APPLICATION:

ROOF DECK SEAM TAPE can be installed on any exterior grade solid sheathing normally used for roof decking. Apply tape only in fair weather conditions when air, roof deck and tape temperatures are at 40°F (4°C) or higher.

Install tape such that all laps shed water in both vertical and horizontal installations. Install tape starting at the lowest point of roof slope and work up the slope. Peel back roughly 6″ of the release liner, center over the seam, apply tape and align. Continue removing release liner as tape is unrolled into place over seam. Allow 4″ to 6″ overlaps between pieces of tape, if possible. Apply in shingle-like fashion so that water flows over the lap, not against it. Tape should be firmly pressed or rolled to ensure a positive seal.

LIMITATIONS:

Not recommended for roofs that exceed 250°F (121°C) operating temperature. Not recommended for use on roof slopes less than 2″/12″ (without approval). Not

recommend for use over granulated surfaces or existing roof coverings.

* Note: Copper, Cortin and Zinc roof components are considered highly conductive metals and can reach temperatures exceeding 250°F (121°C).

CAUTION:

ROOF DECK SEAM TAPE should not come into contact with solvent based products, polysulfide’s, plasticized PVC roofing materials or high concentrations

of resins (pitch). ROOF DECK SEAM TAPE incorporates a slip resistant surface; however, Protecto Wrap Company recommends the use of appropriate fall

protection when installing roof underlayments. ROOF DECK SEAM TAPE is a waterproof, air/vapor barrier; spaces under the area covered must be properly

vented.

LIMITED WARRANTY:

This product is covered by the Protecto Wrap Standard 10 year Limited Warranty.

AVAILABLE SIZES

4″ x 66′ Roll

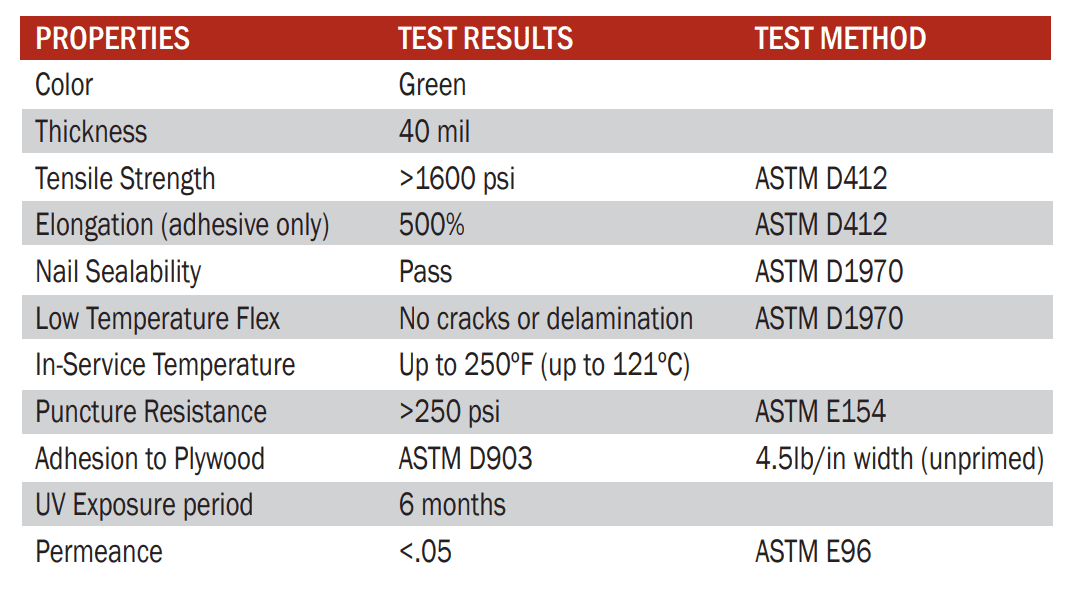

TECHNICAL PROPERTIES

ROOF ASSEMBLIES TO BE ADOPTED EFFECTIVE OCTOBER 1, 2018

(Amd) 8905.1.1 Underlayment. Underlayment for asphalt shingles, clay and concrete tile, metal roof shingles, mineral-surfaced roll roofing, slate and slate-type shingles, wood shingles, wood shakes and metal roof panels shall conform to the applicable standards listed in this chapter. Underlayment materials required to comply with ASTM D 226, D 1970, D 4869 and D 6757 shall bear a label indicating compliance to the standard designation and, if applicable, type classification indicated in Table R905.1.1(1) A minimum 4-inch-wide (102 mm) strip of self-adhering polymer-modified bitumen membrane complying with ASTM D 1970, installed in accordance with the manufacturer’s instructions for the deck material, shall be applied over all joints in the roof decking. Underlayment shall be applied over the entire roof and over the 4-inchwide (102 mm) membrane strips and shall be applied in accordance with Table R905.1.1(2). Underlayment shall be attached in accordance with Table R905.1.1(3).

Exceptions:

1. As an alternative, self-adhering polymer-modified bitumen underlayment complying with ASTM D 1970 installed in accordance with both the underlayment manufacturer’s and roof covering manufacturer’s instructions for the deck material, roof ventilation configuration and climate exposure for the roof covering to be installed, shall be permitted.

2. The 4-inch-wide (102 mm) strips of self-adhering polymer-modified-bitumen membrane are not required for roofs sheathed with lumber having a nominal width of less than 3 feet (914 nun).