These versatile moulding profiles are used by contractors and carpenters to solve a variety of moulding and trim needs in many areas of a home.

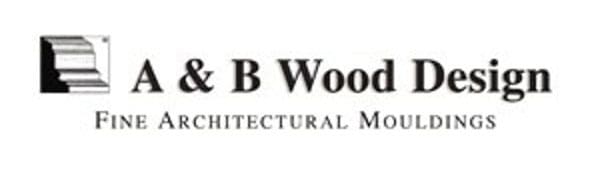

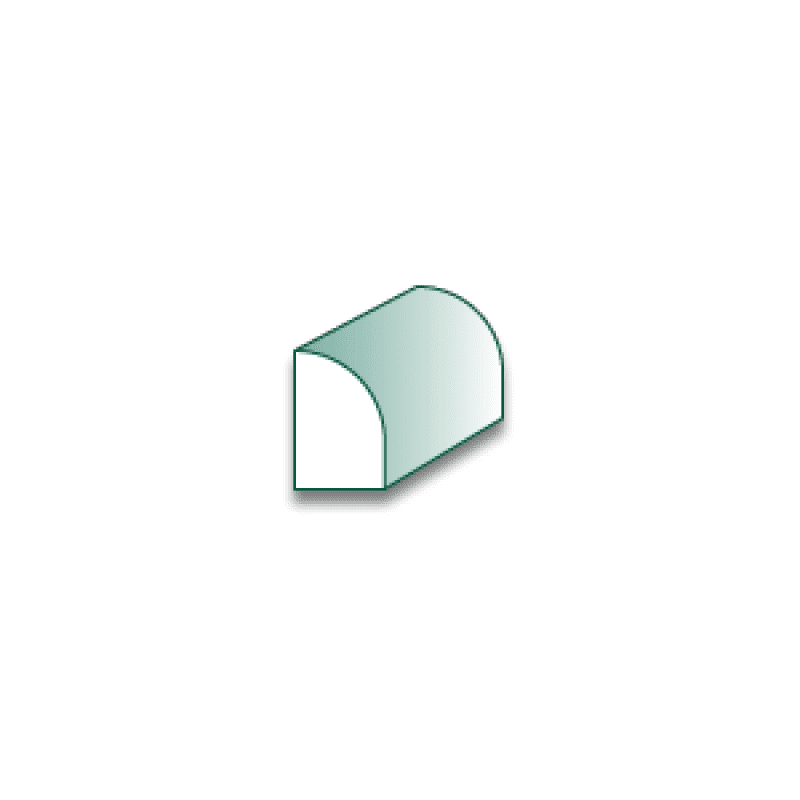

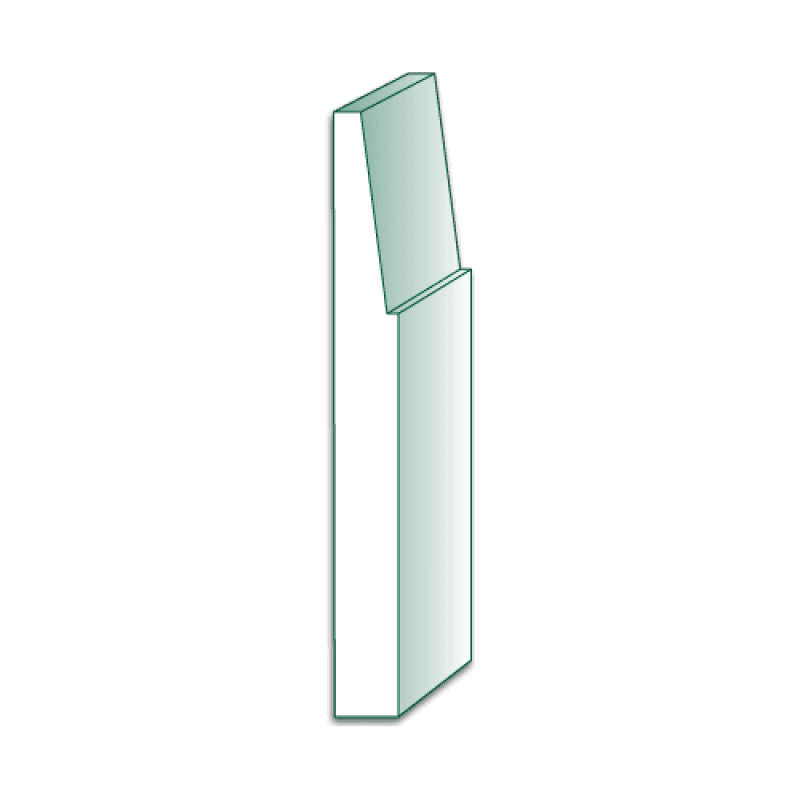

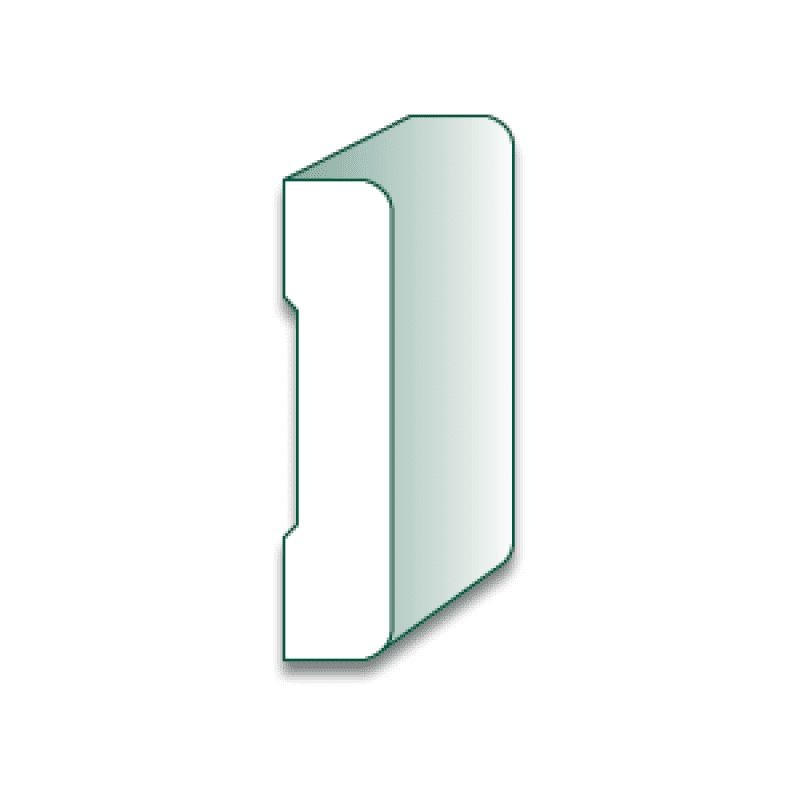

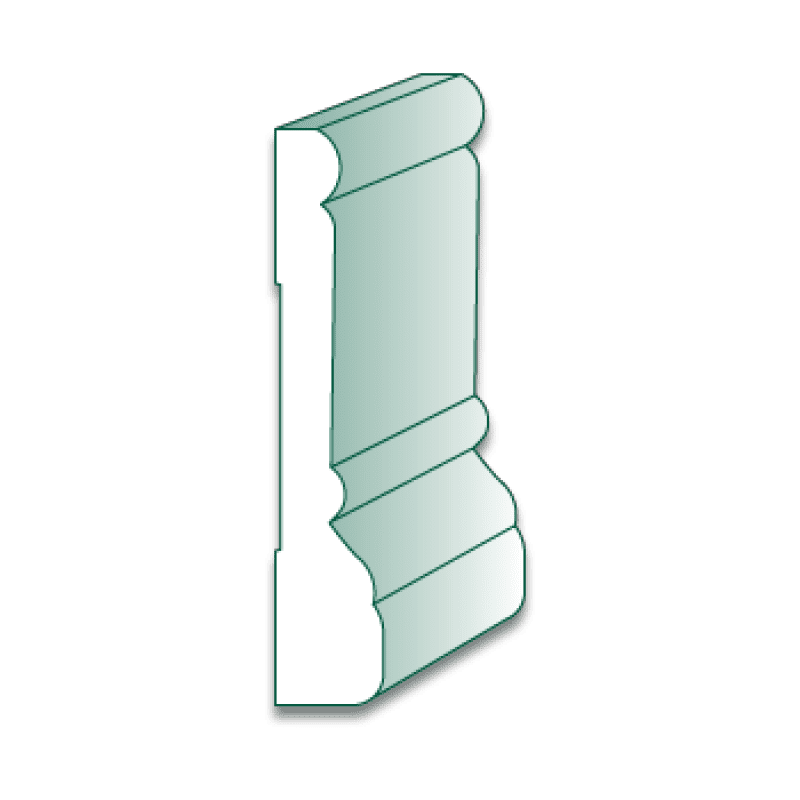

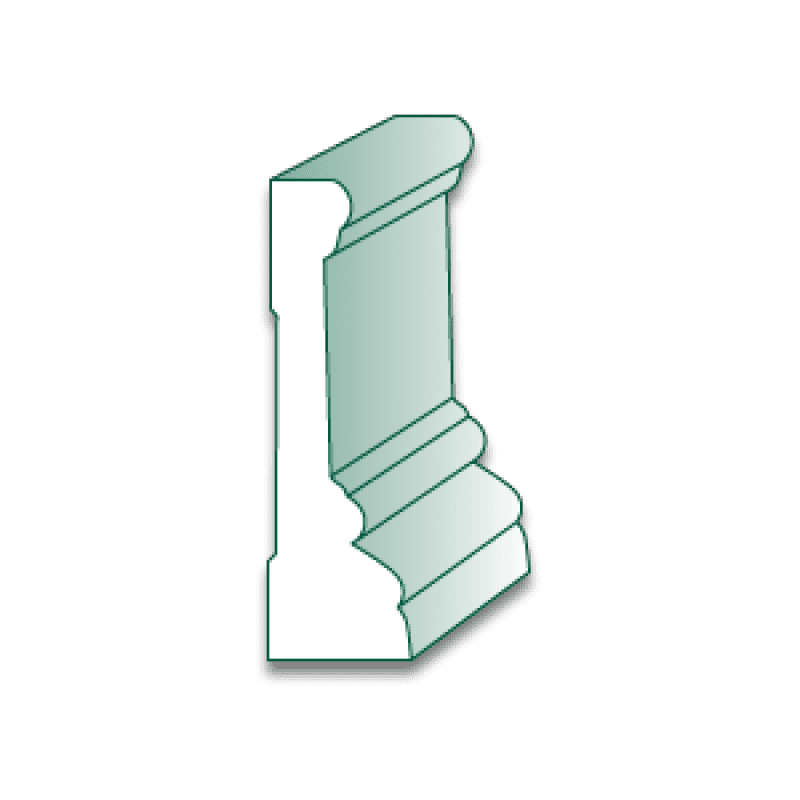

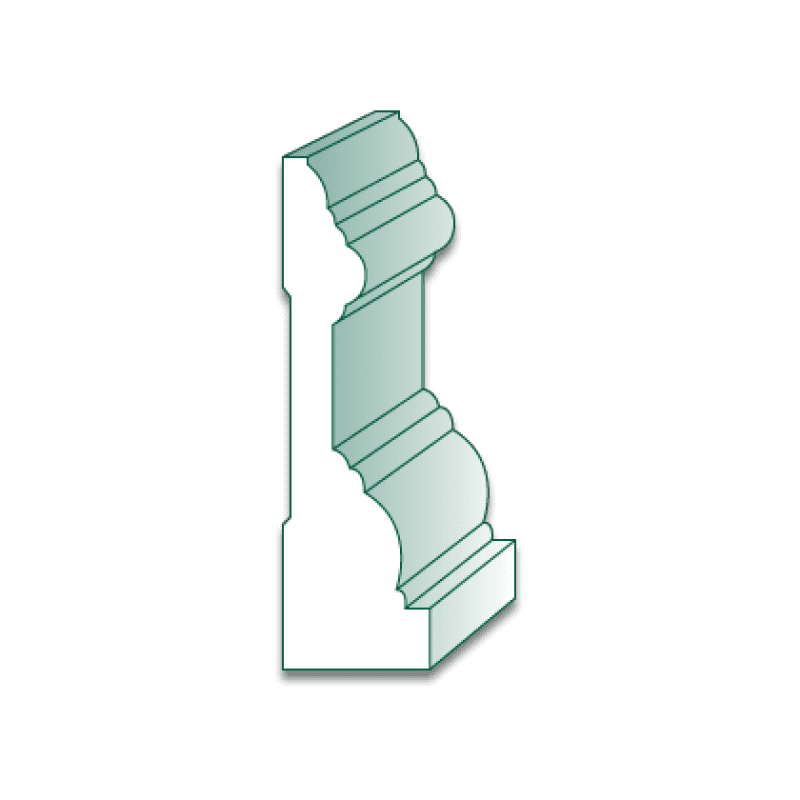

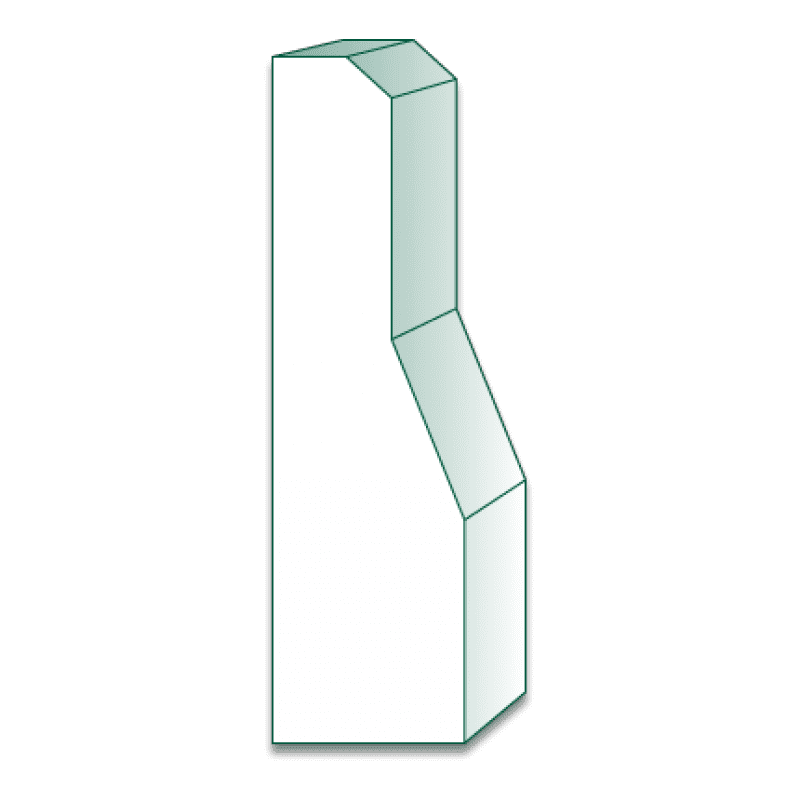

Baseboard caps are applied to the top of regular baseboard to create a more finished and architecturally-complex appearance. Baseboard shoes are primarily used in tandem with traditional baseboards to hide inconsistencies between the floor and the baseboard. They can also be used as a finished trim piece.

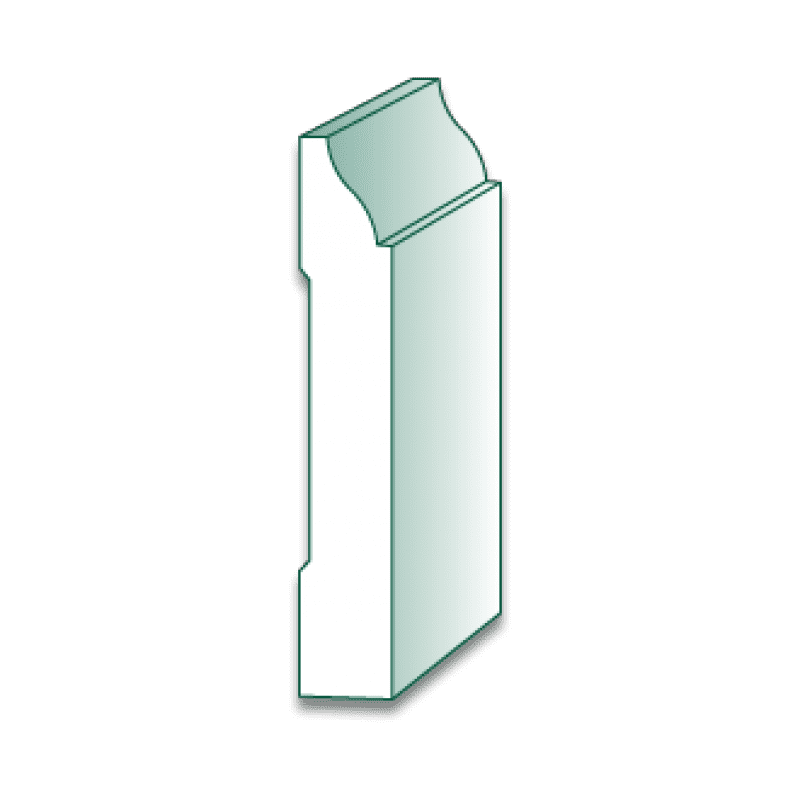

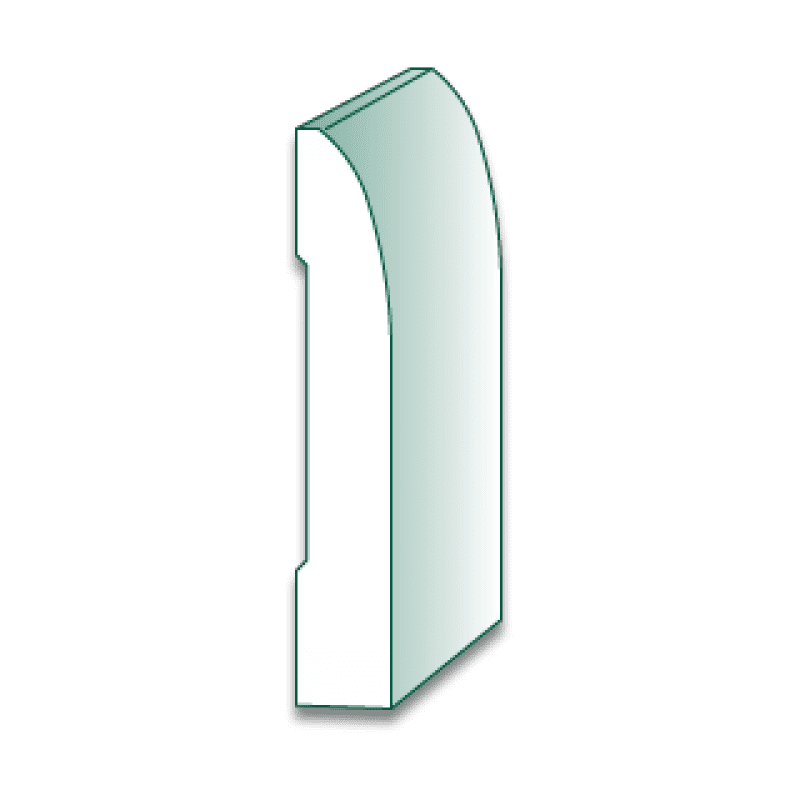

We have hundreds of profiles available from a number of leading manufacturers. Below is a sampling of our most popular baseboard, shoe, and base cap moulding profiles.

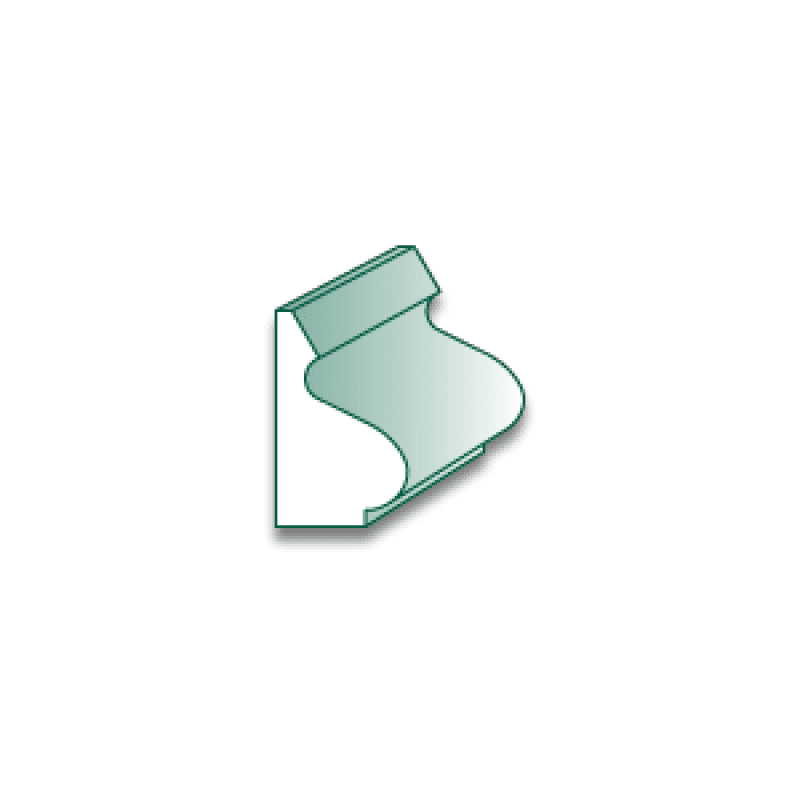

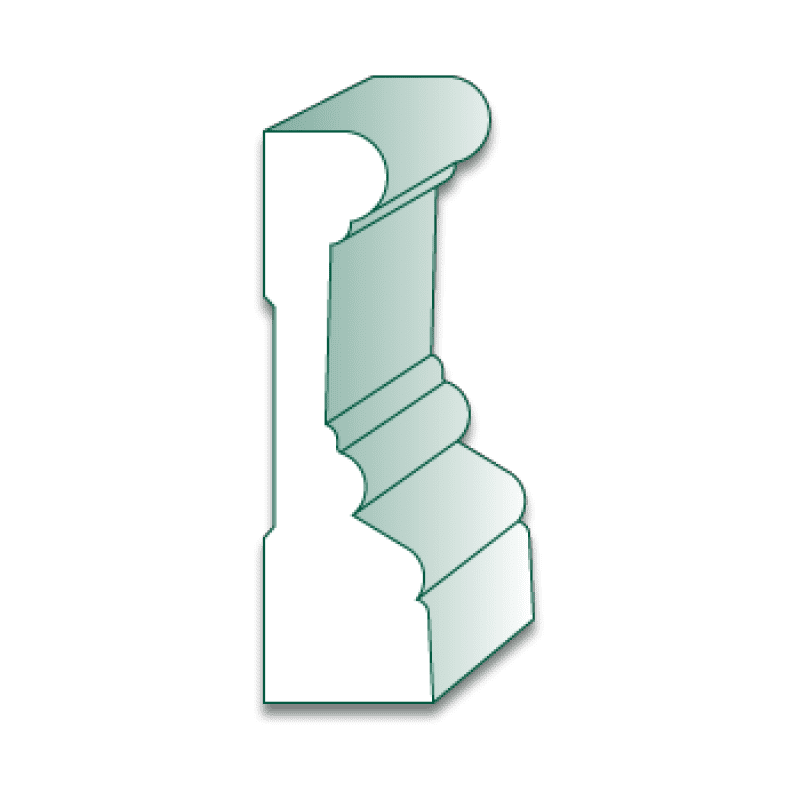

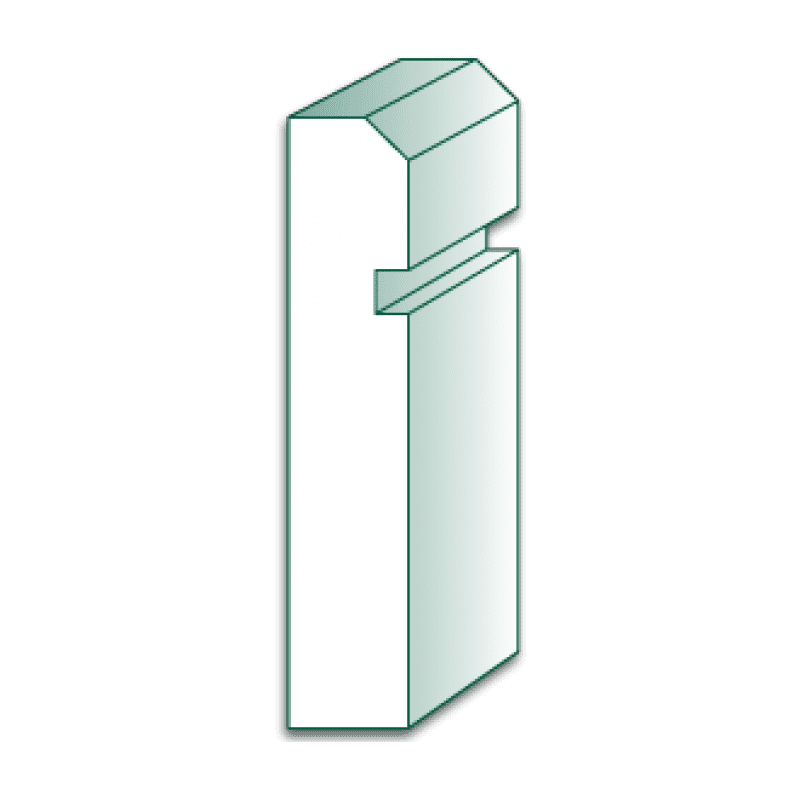

Casing is the moulding profile that frames a door or a window. Casing can serve a functional purpose (such as covering the gaps or spaces between the drywall and framing) or serve as a decorative adornment.

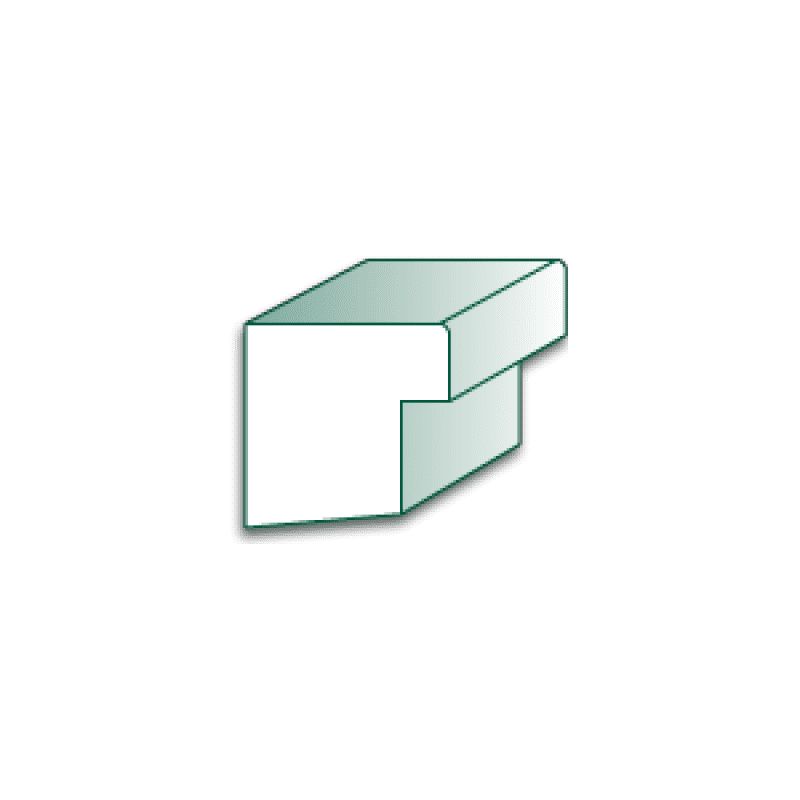

Backband adds architectural interest to standard door and window framing. It can be a secondary dimension to the casing or provide a classier look. Plinth is historically the square base or platform that supports a column or structure. In contemporary design, plinth is used at the bottom of door casings or the corners of windows casing for more dramatic design.

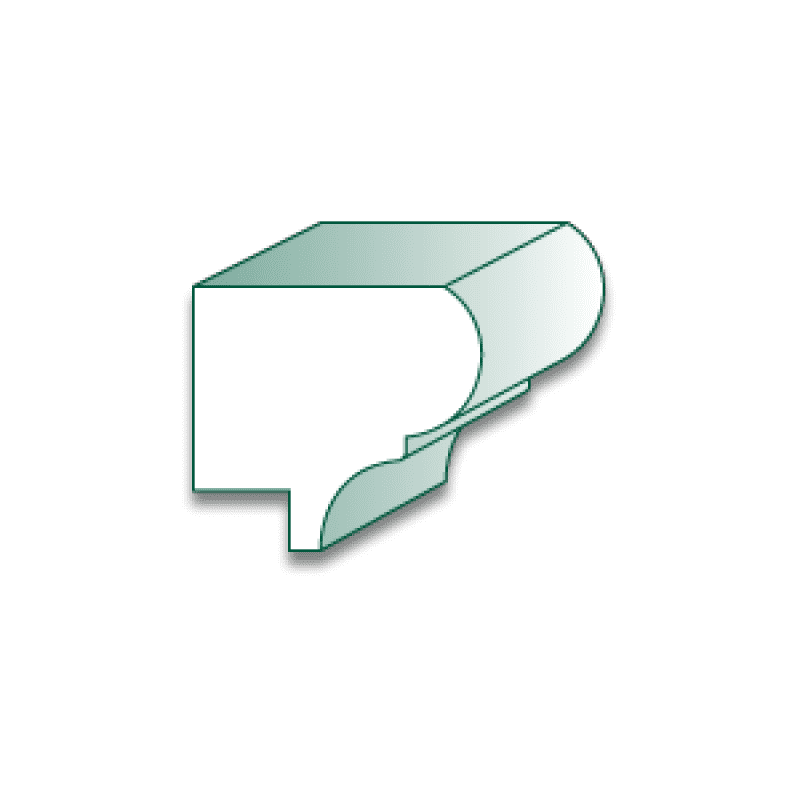

Nothing makes a room feel more grown-up, classy, or opulent than custom crown moulding. It adds a stylish and elegant look that will increase the value of a home, while also concealing inconsistencies where walls and ceilings meet.

Crown mouldings come in a variety of widths to suit small rooms with low ceilings, or larger rooms with vaulted or cathedral ceilings. Experiment with different profiles in different rooms to create interest or a unique feel.

Wood paneling has become a popular design technique once again and can be customized to fit any type of space. It’s a perfect solution for turning a dull and cold space into a warm, cozy interior.

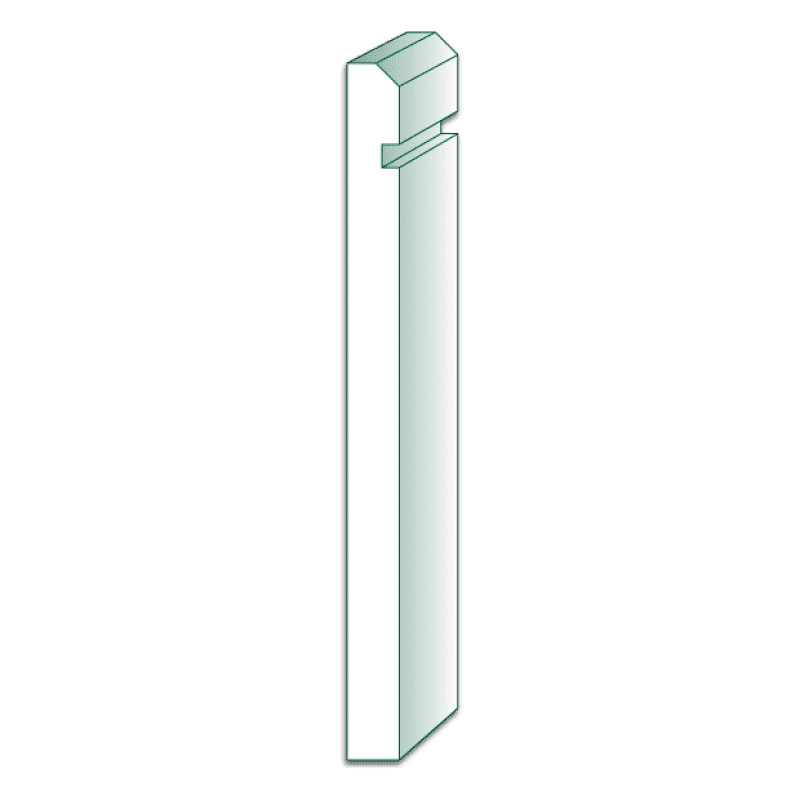

One of the most popular types of paneling is shiplap. Shiplap is usually applied horizontally and the panels overlap to provide its signature style. The boards are connected with rabbets that fit together tightly, forming a waterproof seal.

Other styles of wood paneling are tongue and groove, board and batten, reclaimed wood, flat panels, and beadboard.

Shiplap vs Tongue and Groove

Shiplap vs Tongue and Groove – A shiplap has a notch in the board halfway though called a rabbet. Each edge of the board is rabbeted on opposite faces, so the boards nestle together. Tongue and Groove (T&G) is when the notch is cut on the front and back faces on one edge and in the center of the other edge. Sometimes the edge of one face is beveled, giving the boards a “V-Groove” when pushed together. Any of these options can be ordered as natural or primed, smooth or rough sawn.

Wainscoting

Another general term, wainscoting is paneling that goes partway up a wall, typically a third to halfway. This can be done using a beaded board or panel, shiplap, tongue and groove, or made using raised panel moldings.

What is Nickel Gap

Regardless if a board is milled as shiplap or tongue and groove, it can be milled to fit tight together, or so that when the boards are abutted with a slight spacing called Nickel or Shadow Gap.