Architectural and Performance benefits of Cellular PVC Cladding

What Is Cellular PVC?

PVC that is extruded and whipped into less dense aerated foam—has the working characteristics of wood

- High- end coating ensures a long-lasting ultra-low maintenance finish

- Flexible coating will not chip or crack

- Protects against mold and mildew

- Proven to withstand harshest weather conditions – in real world and simulated testing, resulting in superior fade protection on even the darkest colors

New Technologies

Technological advances have led to superior, water-based, PVDF-coated cellular PVC cladding system

Performance goals for a superior, exterior cladding system:

- Aesthetics

- Durability

- Long-Term Maintenance

Seams

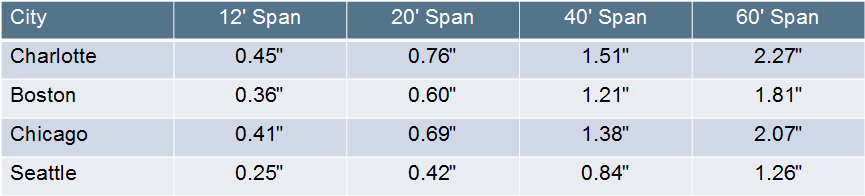

Continuous expansion and contraction of cladding materials creates unsightly “seams”

- Cellular PVC expands/contracts according to temperature change

- Coefficient of expansion for cellular PVC:

- 4.23 x 10 (-5) mm/mm/degree C

Results

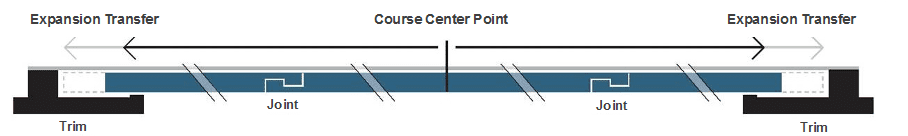

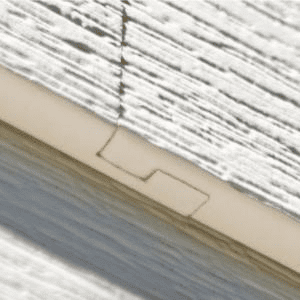

Joints have attractive butt edge

No buckling or gapping

Cladding is free to move at edges during temperature cycling

Moldings and Trim

Flexural strength of cellular PVC is 2,700 psi

Strong and lightweight, can be “heat bent”

Coated plugs conceal the fasteners for smooth surface

PVDF Coatings: Weather ability

A weather able coating:

- Allows product to be installed at-grade

- Allows product to be installed within ½” of roof lines

- Allows product to perform better in high moisture climates

- Allows for better performance in wide temperature cycle zones

Long-Term Maintenance and Recyclability

A solar reflective coating:

- Select and specify a product that can extend or maximize a building’s life cycle

- PDVF coatings allows building owners to avoid having to re-coat or spend maintenance dollars

- PVDF coatings can easily be cleaned with a garden hose and a cleaning agent when necessary

- Cellular PVC and water-based PVDF coatings are both recyclable, where facilities exist

- Both post-industrial and post-consumer waste can be recycled

- Packaging should be recyclable—depending on the manufacturer

- Keeps the substrate cooler with lower heat build

- Translates into comfort and lower energy costs

- Keeps surfaces cooler and less susceptible to accelerated aging

Installation & Applications

- Job sites are clean; no harmful airborne particles generated

- Final panel “cuts” used to begin the next course; very little scrap is produced

- No caulking or re-caulking

- No painting or repainting

- Product can go to grade

- ½” from rooflines

- One product for all climates

- 200 MPH+ wind ratings

- All hidden fasteners

- Multiple profiles